The artisan's sensibility creates the "best comfort" - A conversation between Daichi Kamino and the president of a long-established sock manufacturer (Part 2)

Text: Yuki Yoshida

Daichi Kamino's brand , RETO, will begin selling running socks in April 2022. The product was developed in collaboration with UNIVAL Co., Ltd. , which has its own factory in Kakogawa City, Hyogo Prefecture, one of Japan's three major sock production areas, and took about a year to complete.

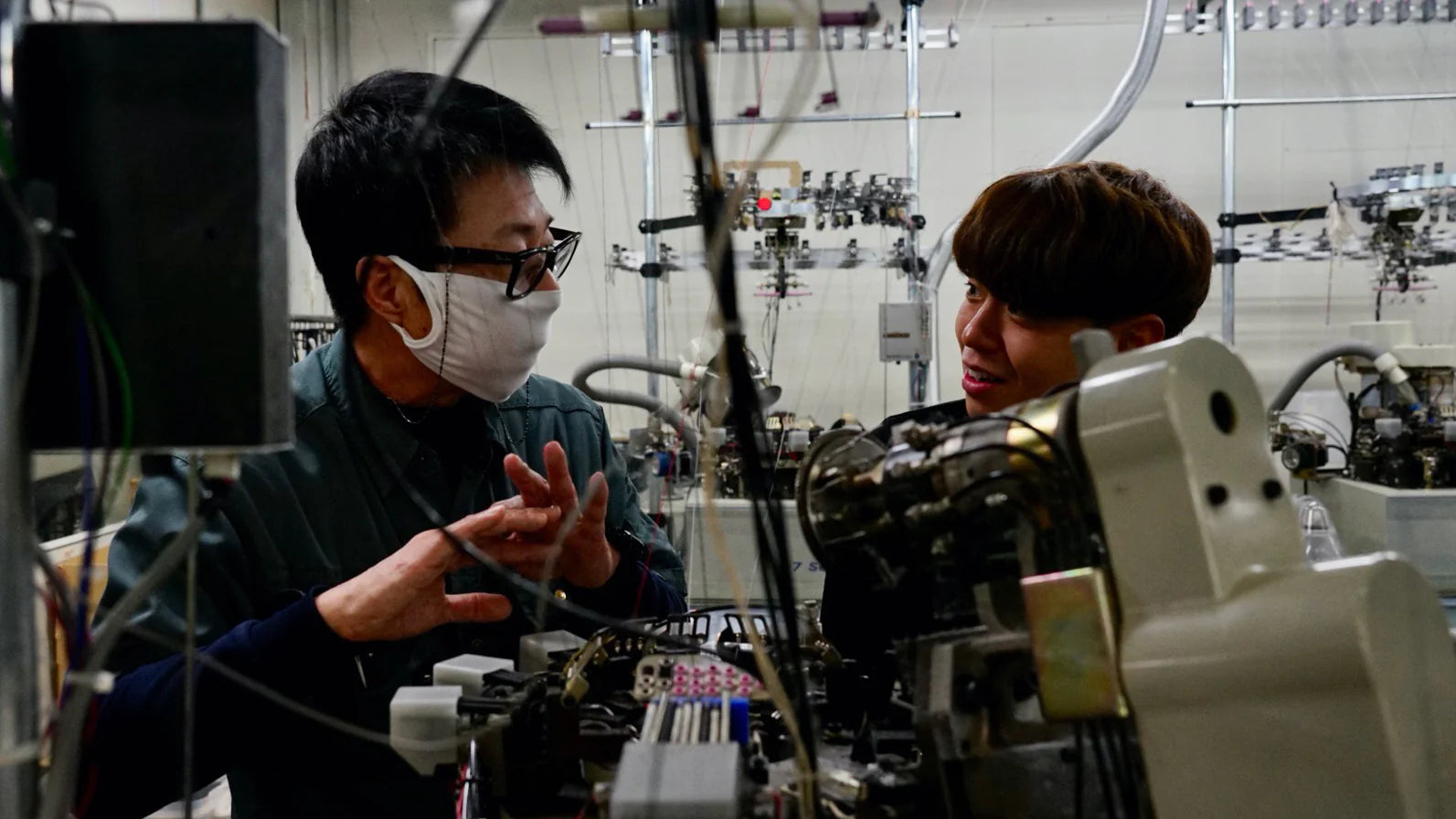

In February, we actually visited the factory in Kakogawa City, Hyogo Prefecture. In this article, we will reveal the conversation that took place between UNIVAL's President Yokoyama and Kamino after the factory tour.

In the second part, we will take a look at the inside story of sock manufacturing, which is something that we don't usually have a chance to know about. You will get a glimpse of President Yokoyama's attention to detail and passion for manufacturing.

When running, wear the best socks for running.

Kamino: Listening to you talk, socks seem to be very delicate. They take a long time to make and aren't particularly expensive, but is there any particular reason why you continue to focus on socks?

Yokoyama: That's right. Our company is now in its 56th year, including manufacturing. My father was the founder, and I am the second generation to run it.

Sock manufacturing is a local industry in Kakogawa City, Hyogo Prefecture. I also heard this from my father, but Shikata-cho in Kakogawa City used to be a place where cotton was grown, and that's how socks were born here. I've heard that even earlier, someone brought back a knitting machine from China and spun the cotton grown here to make socks.

If someone were to ask me, "Why socks?", I would honestly say that I have been carrying on the tradition from my father. Even if you try to make something in the same way, different craftsmen will not be able to produce the same product, and even if you use the same machine, different craftsmen will produce different products. I enjoy these things, and I feel that if I dig deeper, I might be able to do something even more interesting. I think that is why I have continued for so many years.

We believe that health starts from the feet. Of course, shoes support the feet, but socks are also a part of that, and we believe they are one way for everyone to live a healthy and happy life. We feel that we continue to do this because we have the desire to develop even better products, and to create products that are loved by even more people.

Jinno: There are so many different types of socks out there, and some that can be bought for just 100 yen. We were talking earlier about how health starts from the feet, but when I was in high school I didn't really care about socks, but after going through a lot of different experiences I've come to realise that socks can improve performance and that it's something that everyone should place more importance on. I hope that those watching this interview will realise that "RETO x IDATEN" are socks that are a little different!

Speaking of which, I just received another product from UNIVAL and am wearing it right now, and it's also very comfortable.

Yokoyama: Thank you.

The socks that Kamino-san is wearing now, "made by a sock maker who likes to wear cold weather," are the warmest socks we have in stock.

There are many different occasions when you wear socks, such as keeping you warm in winter, cool in summer, and absorbing sweat when exercising. As with the seasons, we consider the various occasions when we will be wearing socks and think about what is best suited to each. "RETO x IDATEN" is suitable for running, while "Socks Made by a Sock Maker Who Loves the Cold" are suitable for cold weather, and we are particular about the best comfort for each occasion.

Kamino: So it's about creating something that suits each individual's needs.

Yokoyama: That's right! We create our products with the hope of providing products that meet your needs at the best possible price.

Socks = Human Wave Tactics Our proud socks are packed with craftsmanship

Yokoyama: Finally, let me ask Mr. Kamino one question.

Thank you for coming all the way to Kakogawa City, Hyogo Prefecture today. I've been in contact with Mr. Kamino for the past year, but due to the COVID-19 pandemic we haven't been able to meet in person, so we've mostly been communicating remotely, sending samples and getting feedback. So, as a manufacturer, I'm very happy that you came all the way here today and were able to see how socks are made in our factory.

I'm sure it was partly because the product was completed, but I'm curious as to why they came.

Jinno: Yes, I've been competing in track and field for a long time and have worn a variety of socks, but I've never been interested in how socks are made. However, since I'm releasing products under my own brand, "RETO," I'm simply interested in how socks are made, and I thought I'd like to see if I could.

As expected, when I actually saw it, it was beyond my imagination. The machines were like nothing I'd ever seen before and I felt like I would never be able to operate them myself. I felt that it was an important time to see it for myself.

That machine is really amazing...

Yokoyama: We currently have four engineers working in our factory, all of whom are veterans with 15 to 20 years of experience, some as long as 30 years.

People often say that socks can be made with just one button, but when they come to see our factory they are truly surprised. Even though the world has developed so much, socks are probably the most labor-intensive textile production process, from yarn to finished product, using a human wave tactic.

Kamino: It's a machine, but when I saw it, I could tell it was packed with the skill of a craftsman.

Yokoyama: It's computerized to a certain extent, so it's possible to draw a pattern, but even if you make the same thing with the same machine, it will end up being different. It's like each person's taste. It's like a chef, it's all about each person's sense.

Even if they're given the same materials and the same recipe, there's probably differences in the heat and things like that. It's the same thing with socks. They're using the same yarn and all the same computer data, but when a different worker makes them, they turn out differently. That's the kind of skill that goes into making socks, and it's not something that can be mastered in a year or two, and it's a matter of sensibility, so it's difficult to pass on. I intend to pass it on, but I feel it's difficult for younger people to pass it on. Socks are such intricate and delicate products, so I'd be happy if people could understand that.

Kamino: That's what I felt when I saw it today.

I was also involved in the final part of the work, but it was completely different when I did it than when the craftsman did it, and there were some inconsistencies in my work, so I realized that there is a difference between when a proper person does it and when I do it, and that doing it one step at a time prevents inconsistencies.

It would be a problem for the buyer too if they thought, "This is somehow different from the previous one." When we buy something because we think it's good, we want to think it's just as good again, so that's what I felt when I experienced it myself: it's a product that's packed with the power of people.

Yokoyama: Thank you.

So, a final word. I hope that you will continue to carry the world of athletics on your shoulders and set new personal records. Finally, as you head towards the full marathon, all of us at Unival Corporation will be praying for your continued success, naturally wearing "RETO x IDATEN" shoes. Please do your best and avoid any injuries.

Kamino: Thank you.

Thank you for chatting with us today!